Plant management

In general terms, the plant is operated from the control room which sends out the requisite number of monitoring and control signals to execute the actions involved in running the plant.

The gas turbine, steam turbine and other packaged plant facilities located at the site such as the water treatment plant, the chemical dosing unit, seawater filtering unit, etc, all have their own control panels so that they can be operated locally. These local panels are linked to the plant´s distributed control system when sends out commands controlling the main functions they perform.

General plant layout

The plant´s buildings and facilities are located in a relatively compact area. Industrial architectural criteria normally applied to this type of plant have been used to design the buildings. The various zones that make up the plant are described below:

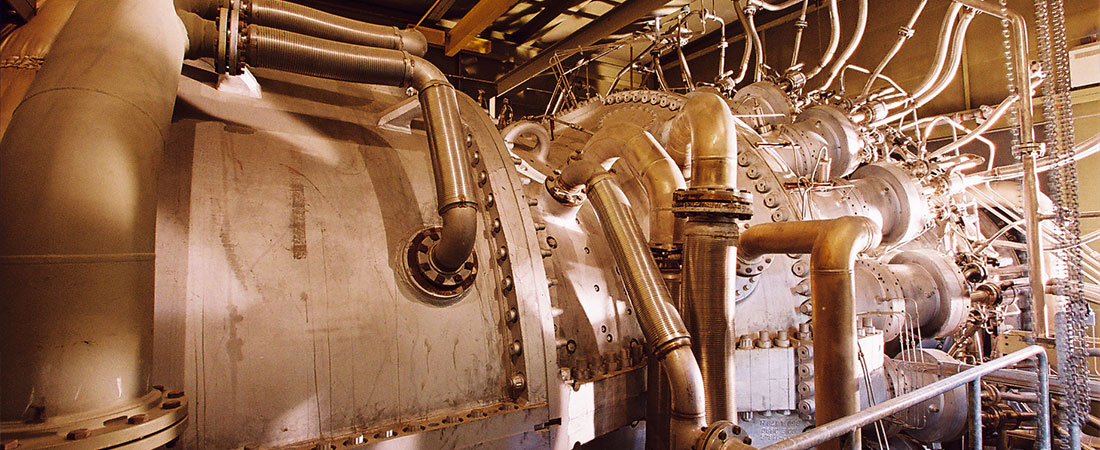

Gas turbine zone

The gas turbines and their auxiliary systems are housed in a two-storey building. The turbine´s air intake filters are supported on the lowest section of ceiling in the building. Two overhead travelling cranes have been installed for maintenance purposes, one in the turbine zone and the other in the turbine generator zone.

Steam turbine zone

The steam turbine stands on a platform with the condenser situated beneath the low-pressure stage exhaust. The turbine´s auxiliary facilities (oil, lubrication, electrical support unit, hydrogen sealing oil, etc.) can be found on the mezzanine floors. The overhead travelling crane runs parallel to the turbine shaft and can access all areas.

The water supply pumps are located at ground level between the turbine building and the electrical control room. The degasifier is situated above them on the same level as the turbine.

Transformer zone

The main transformers can be found between the turbine building and the substation, facilitating output towards the latter.

Heat recovery steam generator zone

The heat recovery steam generators are housed inside a covered facility. These boilers are connected to a 125-m smokestack with a concrete shaft and independent gas pipes for each boiler.

Electrical control room, main control room and offices

The electrical equipment rooms and the chemical laboratory are on the ground floor. The main control room is on the top floor, right above the electrical equipment rooms. Alongside are the general offices, which sit above the laboratory.

Pipe rack zone

A pipe rack runs between the gas turbine and boiler buildings and carries the main and auxiliary pipes.

Auxiliary plant zones

The water treatment units, sewage tanks, and the compressed-air and fire-prevention systems are located right by the entrance to the facility.

Information on the construction of the Bahía de Bizkaia Electricidad S.L. (BBE).

GENERAL INFORMATION

- Promoter: BP, EVE, Iberdrola eta Repsol YPF.

- Author of project: UTE BAIA: Babcock Borsig España, Abengoa; Idom.

- Engineering Project Management: Iberinco.

- Project Engineering: Idom.

THERMAL CYCLE

- Gas turbine: General Electric.

- Generators: General Electric.

- Cleaning of compressors: Eusitrade.

WATER-VAPOUR CYCLE

- Waste heat boilers and boiler valves: Babcock Borsig España.

- HP/LP vapour tempering: Comeval.

- Water supply pumps to boilers: Flowserve.

- Vapour bypass system: CCI Valves.

- Steam turbine: General Electric.

- Generator: General Electric.

- Concrete chimney: Edytesa.

AUXILIARY SYSTEMS

- Auxiliary boiler: Standardkessel Ibérica.

- Condenser: Babcock Borsig España.

- Condensed pumps: Flowserve.

- Condensed tank: Iberfuel.

- Vacuum pumps: Nash.

- Condenser cleaning system: E. Beaudrey.

MAIN COOLING

- Sea water filtration: E. Beaudrey.

- Sea water circulation pipe: Noncales.

- Water circulation pumps: Flowserve.

- Electric motors: Indar.

- Minimum cooling service pumps: Flowserve.

- Condenser cleaning of the water cooling system:E. Beaudrey.

- Butterfly and back pressure valves: Babcock Borsig España.

AUXILIARY COOLING

- Plate exchangers: Alfa Laval.

- Compensation tank: Noncales.

- Circulation pumps: Flowserve.

- Dosing system: Dosapro.

- Instrumentation: ABB.

GAS SYSTEM

- Measuring Equipment: Instromet Gas.

WATER TREATMENT

- Demineralization Plant: Ondeo-Degremont.

- Water Tanks: Iberfuel.

- Treated Water Impulsion Pumps: Bombas Itur.

EFFLUENT TREATMENT

- Treatment Plant: Ondeo-Degremont.

POWER SYSTEM

- Main transformers: ABB Trafo.

- Auxiliary transformers: ABB Trafo.

MEDIUM VOLTAGE BAR SYSTEM

- Wiring system: ECN Cable.

- HV/MV network assembly and instrumentation: Isotrón.

LOW VOLTAGE BAR SYSTEM

- LV and MCCs general panel: Consonni.

- Batteries: Jema.

- CC switchboard:

- Safe power system: Jema.

- Emergency diesel groups: Cymasa

- Internal and external lighting: Tecuni/Isotrón

SUPERVISION AND CONTROL SYSTEM

- Distributed control system: Yokogawa.

- GT-Mark V: General Electric.

- ST-Mark V: General Electric.

MECHANICAL ASSEMBLY

- BOP equipment, boiler and piping: Babcock Montajes/Nervión Montajes and Mantenimienetos.

- Power train: Tamoin Power Services.

- Seawater intake assembly and chlorination system: Babcock Montajes/Nervión Montajes and Mantenimienetos.

- Feed water intake assembly: Babcock Montajes/Nervión Montajes and Mantenimienetos.

- Main hoisting operations: Lastra.

- Overhead cranes: Industrias Electromagnéticas G.H.

PIPES

- Rigid and elastic supports for pipes, boiler and auxiliary lines: Pihasa.

- Pipe system: TSE.

- Alloyed steel main vapour pipes: Fabricom.

- Pipe blasting: Brambles.

- Steel pipes: Tubacero.

VALVES AND DRIVERS

- Control valves: Emerson Process.

- Electric actuators: Rotork.

ENVIRONMENTAL IMPACT STUDY

- Definition, coordination and drafting of the study: Idom.

- Study of atmospheric and noise impact: Labein.

- Study of the hydrodynamic and scattering of heat in the marine environment: Azti.

- Study of land biota and avifauna: Ekos.

OTHERS

- Civil works: Seridom.

- Marine/emissary civil works: Ferrovial.

- Compressed air system: Atlas-Copco.

- Emissions monitoring system: ABB.

- Pressure and temperature instrumentation: Instrumentos Wika.

- Sample taking: Siemsa.

- Cathodic protection: WWI Procat.

- Fireproofing: Pacisa.

- Heating and air-conditioning for control building and offices: Microclima.

- Pipe blasting: Brambles.

- Chemical cleaning: Berako.

- Visualization wall: Aplein Ingenieros.